Equipment Maintenance

Reiko Piekarski, Director of Coffee Programs | Fortuna Enterprises, LLC

Ask any coffee shop owner and they will agree the espresso machine is a huge investment for the business. It is the engine which keeps the café running after all. In fact, most espresso machines cost as much as a new or used car. Just as one would take their vehicle for inspection and routine maintenance a shop owner should manage the same level of care for their coffee equipment. Developing a basic understanding of equipment along with a regularly scheduled program of cleaning and maintenance will keep these essential elements of the business running smoothly.

Water Filtration Maintenance

When it comes to making coffee or espresso, it is important to remember we are using two ingredients: coffee and water. Water quality not only effects the flavor, but it can also impact the equipment performance. When installing equipment, we highly recommend including the water filtration system as to not void the warranty. Filtration keeps out chemicals which can cause corrosion and leaks as well as additional mineral deposits which cause blockages. Filters are maintained by replacing the cartridges annually for medium to low volume businesses and every 6 months for high volume shops. Keeping up with a regular filtration maintenance will achieve better consistency in beverage quality and equipment performance all around.

Routine Cleaning Practices

Clean, clean, clean! Consistent and regular cleaning is key to prolonging the life of equipment. Having an accessible cleaning tool kit behind the bar and proper training with staff will encourage good operational practices. With every drink preparation the barista should always flush the groupheads between every extraction as to knock off any coffee residue from the dispersion screen and group. Buildup of particulate in these areas will degrade the gasket over time which will not ensure a tight and secure seal when the barista locks in the portafilter basket. These gaskets will lose their grab over time but there is no reason to encourage the wear with poor cleaning. Get in the habit of using a brush to clean out the cowling where the portafilter wings lock into the group as time allows throughout the business day to keep this clear of buildup.

Purging and wiping down the steam wand before and after each pitcher of milk steamed will ensure there is not build up of residue around and inside the steam wand. Proper purging of the steam wand will also prevent milk backflow into the boiler. Simply pouring hot water down the drain tray and through the drain line will also ensure there is proper flow away from the machine to prevent any blockages.

Most importantly, at the end of each business day the machine should be thoroughly cleaned and flushed. Backflushing with the espresso machine detergent like Cafiza breaks up coffee buildup from the day from the group, dispersion screens and lines. It is imperative to rinse thoroughly after running the cleaner as to not leave any cleaning product to re-crystallize in the solenoid overnight causing blockage. Similarly, the Rinza is used to breakup any fats and proteins remaining on and in the steam wand at the end of the day.

Preventative Maintenance

Making sure a cleaning routine is consistently and regularly applied will go a long way in preventing catastrophic failures. Scheduling a routine checkup or a preventative maintenance will add the extra assurance equipment will run at its peak performance. These appointments also give the technician an opportunity to check and fix any smaller issues they may observe. Leaving something unchecked can lead to a bigger problem down the line and in worst case scenarios a business without a working machine all together. Knowing how to clean and managing basic maintenance in the shop is valuable however it is also important to know when to schedule an appointment with a coffee technician. Below is a chart to help determine the best course of care for an espresso machine.

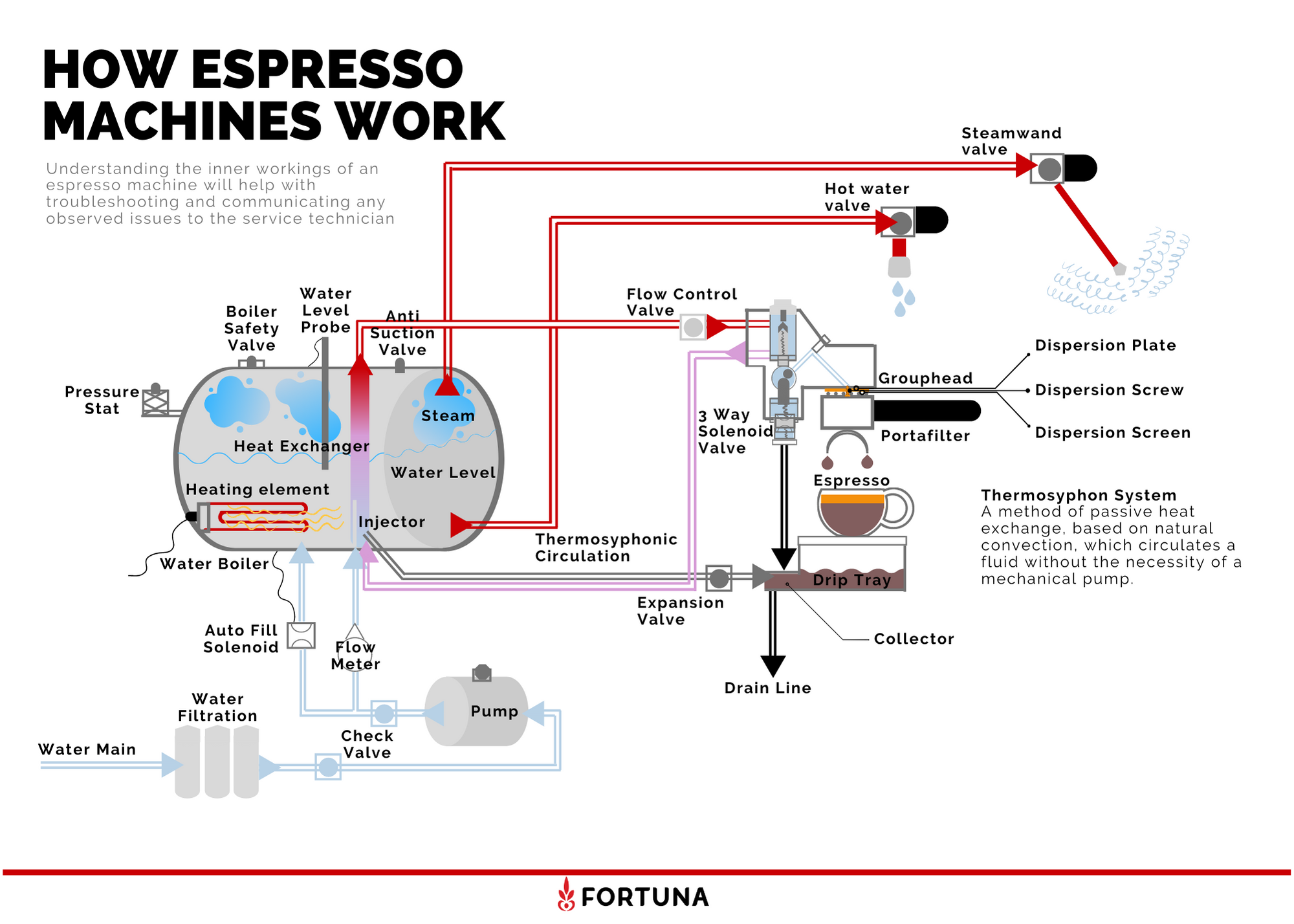

The main takeaway from all this is simple. Establish a routine maintenance schedule and ensure cleaning protocols are being applied daily. When there is a problem warranting a call for a technician be able to communicate the problem as best as one can. Unsure about what knob, button, or lever does or where the source of the strange noise or leak is coming from? Refer to the diagrams included in this post to develop a more complete understanding of how the espresso machine works. Feeling more confident in understanding how the machine works will put the customer in better position to effectively communicate a problem. Above all, remember when in doubt call a coffee technician.